This article originally appeared in the November 2014 edition of ABRN.

When friends and family think about the vehicles of yesteryear they often say to me "they don't build them like they used to." I tell them, you have no idea how right you are. Cars today are light years ahead of where they were just a few short years ago. It is no longer vehicles of the future we are discussing, but current vehicles on the road today, and some are being repaired like nothing has changed. With the major changes in vehicle construction, the collision repair industry will need to learn some advanced attachment methods and a new way of thinking. Lets take a look at some advanced attachment methods necessary for repair on vehicles that are on the road today.

MIG Brazing

MIG brazing is used for many different reasons. It can be used to make continuous weld joints on panels where warping, or overheating heat-sensitive materials are a concern. MIG brazing is also used to make slot welds when attaching heat-sensitive materials, and where recommended in vehicle maker repair information. Most of the MIG brazed joints are used to attach a lower strength steel part to a higher strength steel part that is heat sensitive. Another benefit of MIG brazing is that it is softer than steel, allowing it to be more easily shaped and finished. (See Figure 1)

The MIG brazing wire tensile strength is approximately 275–350 MPa but the MIG brazed joint may be stronger than that if done correctly, due to the thickness of the bead on the backside.

The filler metal, which is usually silicon bronze, melts at a lower temperature than the steel base metal. (As a side note, MIG brazing cannot be used on aluminum panels because silicon bronze melts at a higher temperature than aluminum.) The molten filler metal is drawn into the joint by capillary action. In order to have a successful repair when MIG brazing, capillary action is required for a strong joint. Capillary action is the process in which the molten filler metal wicks or spreads out along the backside of the repair joint. The filler metal then bonds to the base metal.

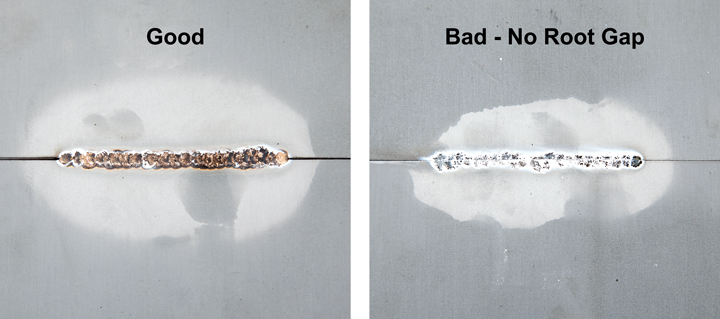

Figure 2 - Without the correct root gap capillary action will not occur.

Figure 2 - Without the correct root gap capillary action will not occur.

When you make MIG braze joints, try using a manual stitch to control the heat affect zone (HAZ). This technique works well when using a GMA welder that has silicon bronze wire instead of steel wire. There are some machines that have a preprogrammed setting for MIG brazing. These machines also have adjustments for electrode size, material thickness, and electrode alloy. The goal on an open butt joint is to create a weld bead on the backside that is almost indistinguishable from the front side bead. (See Figure 2)

The natural tendency when someone starts to MIG braze is to turn up the welder in order to get the bead to look the same as when GMA welding. This is both unnecessary and detrimental to the repair joint. It will dramatically increase the HAZ, and still may not provide the proper amount of capillary action.

Another critical part of MIG brazing is to keep the proper root gap to ensure that the brazed joint is strong. If the root gap is too small, there will not be enough capillary action taking place. When the front side is ground down, the weld bead on the backside is the only thing that is providing strength to the repair joint.

Just like with GMA welds, you must visually inspect and destructively test practice welds. When inspecting practice welds, look for tearout around the brazed joint the same way as when testing GMA welds. Another destructive test that should be done is the grind destructive test. To do the test, make a weld and grind the front side level with the surface. Then, destructively test the weld. This test will verify that the joint has sufficient capillary action.

Aluminum Welding

Figure 3 - This pulse welder is creating a quality weld bead.

Figure 3 - This pulse welder is creating a quality weld bead.

Next let’s take a look at aluminum welding. For some of the luxury vehicle repair facilities, welding aluminum is nothing new, but for many it is virtually an unknown. First thing that is needed is the right equipment. Most of the vehicle makers require a welder that is capable of welding in the pulse mode. (Check with each vehicle maker requirements for full details.) (See Figure 3)

The next thing that will be needed is training and practice. Aluminum welding is far less forgiving than traditional steel welding. When aluminum welding, surface preparation is absolutely critical to a successful weld. Aluminum, once exposed to air, almost instantly forms an aluminum oxide layer. This non-conductive aluminum oxide layer is extremely hard, has a higher melting temperature than aluminum, and will cause extremely bad welds due to porosity. (See Figure 4)

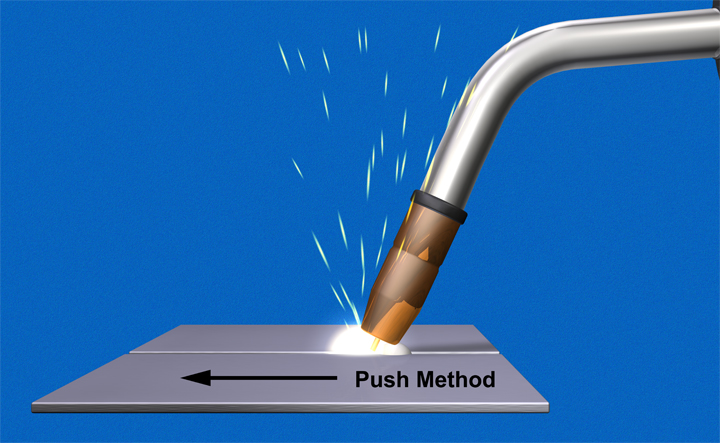

Figure 4 - When aluminum welding, the push technique must be used to create a strong weld.

Figure 4 - When aluminum welding, the push technique must be used to create a strong weld.

If there are any deficiencies in welding technique, aluminum welding will show it in the form of a bad weld. This is where training and practice are going to be key. With steel GMA welding, you can push or pull the weld puddle, and have some success with either method. But with aluminum you have to push the weld puddle. This will preheat the panel ahead of the weld, which will keep a stable arc and allow the shielding gas to protect the welding zone from outside contaminants.

Rivet Bonding

The final attachment method we will look at is rivet bonding, with the main focus being self-piercing rivet (SPR) bonding. This again is not new to those that repair steel and aluminum luxury vehicles. But for the rest of the industry, it is a new concept. The good news is with some new pieces of equipment, and some training, you will have what you need. With rivet bonding, there are some similarities to squeeze-type resistance spot weld (STRSW) bonding that will be familiar.

Figure 5 - This SPR gun is installing replacement rivets.

Figure 5 - This SPR gun is installing replacement rivets.

The similarities are that panel fit up and flange preparation must be a top priority for a successful repair. The jaws of a spot welder will not correct panel misalignment, neither will an SPR gun. If the panels do not align, it will cause a poor quality repair. Also, the flange preparation is critical, so the adhesive can properly attach the panels. And as always, do not forget to prepare the adhesive cartridge following product maker instructions to ensure proper curing of the adhesive. (See Figure 5)

Now, lets look at the required equipment; the main tool that will be needed is a SPR gun. The types of vehicles you are repairing will help determine which gun is needed, the types (blind rivets are often used in conjunction with SPRs) and size of SPRs, and any accessories that are needed for the SPR gun. (Look at the vehicle maker repair information for more details) On the jaws of the SPR gun, there are several different die sets that will be needed, some are used to extract previously installed SPRs, and some to install new SPRs. (See Figure 6)

Figure 6 - This is one of many SPR gun kits that are available.

Figure 6 - This is one of many SPR gun kits that are available.

The final piece of this puzzle is selecting the correct size and type of rivet. The length of the SPR or blind rivet must be matched to the panel thicknesses that are being joined. An SPR that is too long will not form correctly and could leave a hole in the backside of the panel, while one that is too short will not form correctly creating a weak spot in the repair and could cause a repair failure. The best way to determine which SPR is required is to follow vehicle maker repair procedures.

Conclusion

Repairs on today’s complex vehicles are not the repairs of yesteryear. The vast combinations of materials and joining methods from the vehicle maker require the collision repair industry to update their tools, equipment, techniques, training, and thought process. If the industry does not adapt to this new world, complete and safe repairs will become part of yesteryear as well.

Additional I-CAR Collision Repair News you may find helpful:

Print

Print