Close

Your job requires that you keep on top of the latest in vehicle, tool, and equipment technology – I-CAR is committed to helping you do so in one convenient place. We regularly publish new articles highlighting the latest and greatest collision repair information.

So check back often and follow us on X @Ask_ICAR to ensure you’re equipped with the most up-to-date collision repair technical information available in the industry.

What is the MPa of the front lower rail? What is the outer uniside made of: steel, aluminum, or composite? Can heat be used to straighten or is it cold straightening only? What are the repair limitations? These are just some of the questions that the RTS team fields on a daily basis.

Many of the 2015-2020 Ford F-150s come with factory installed running boards. If you have had to replace the inner rocker panel lately, you may have noticed that the replacement inner rocker panel was missing hardware to install the running board after replacement. So, we reached out to our contacts at Ford to find the answer to this problem.

A key part of being able to diagnose a problem with advanced driver assistance systems (ADAS) is understanding how the system works. Knowing what is happening inside the system will help you properly diagnose why the system may be failing. This will prevent replacing parts that are not causing the system issue. Let’s take a look at the inner workings of an adaptive cruise control system (ACC).

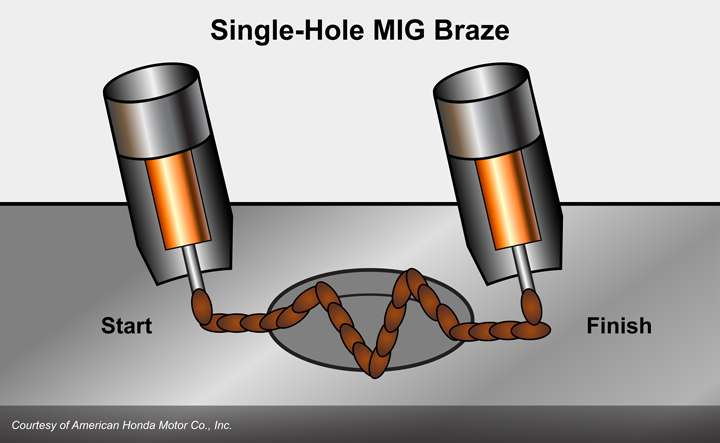

ABRN published an article today titled, "MIG Brazing Basics," authored by Jason Bartanen, Director of Industry Technical Relations at I-CAR. Let’s take a look at this article.

When a vehicle is produced at the factory, speed of production is a major factor for the OEM. This means that a lot of time and money is invested into machines that can produce a quality product in a short amount of time. However, the collision repair industry does not often have access to the same technology used on the factory floor. The OEMs recognize that a method used at the factory will not always be possible during repair. Also, some vehicles have global platforms and the OEMs know that certain products may not be available in all areas of the world. By taking this into account, OEMs create repair procedures to fit the collision repair industry while maintaining the safety and quality that the vehicle had from the factory. So when looking at a repair procedure, the procedure may specify to use a material that was not originally used on the vehicle during assembly. Let’s take a closer look at some of the differences.

What is the MPa of the front lower rail? What is the outer uniside made of: steel, aluminum, or composite? Can heat be used to straighten or is it cold straightening only? What are the repair limitations? These are just some of the questions that the RTS team fields on a daily basis.

What’s on the repair agenda for 2018 GM vehicles? The expanded use of squeeze-type resistance spot welding (STRSW) over plug welds in the collision repair process. Repairer Driven News (RDN) published an article highlighting this upcoming change.

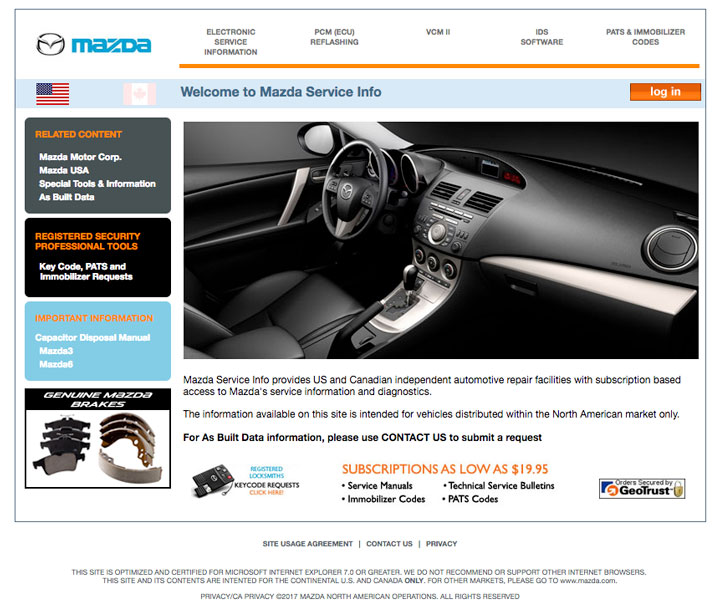

Mazda has redesigned their repair information website. Let’s take a look at the new setup of Mazda’s website.

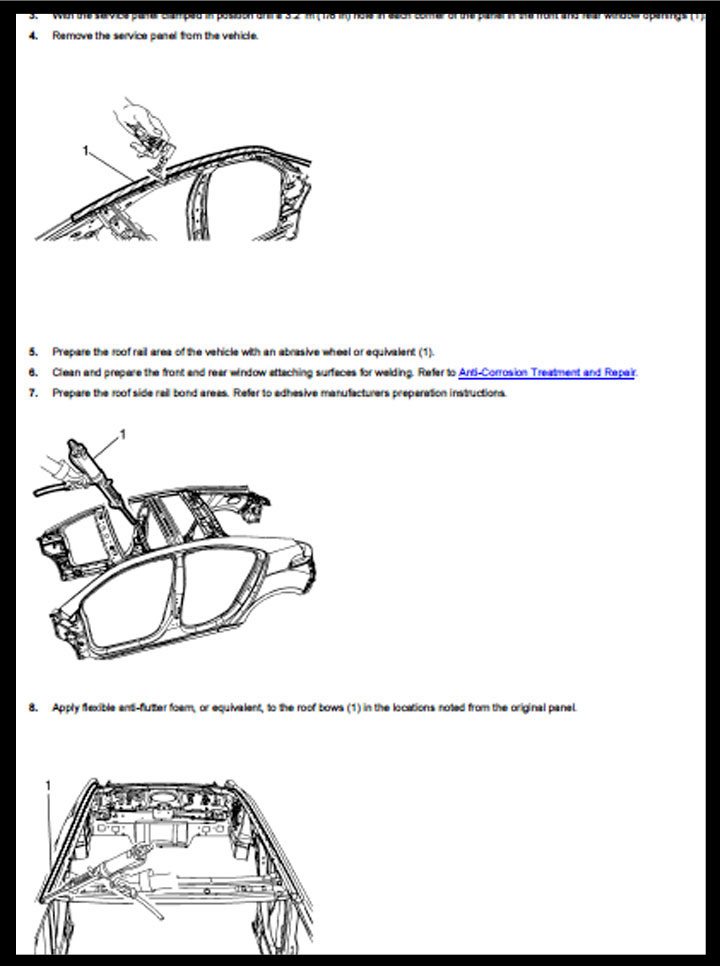

A key factor in collision repair is making long-lasting repairs. When a vehicle is repaired, many areas of corrosion protection are disturbed. This creates corrosion hot spots that left untreated will lead to corrosion and potentially a repair failure. However, there are certain precautions that can be taken to safely and properly restore the corrosion protection throughout the repair process. OEMs often give specifications on restoring corrosion protection. These specifications generally include seam sealer, adhesives, foam fillers, and cavity waxes. Let’s take a look at what Kia says.

The addition of the OEM Calibration Requirements Search to the RTS portal was a big step for the collision industry. While this new feature has been well received, there has been some confusion about what is included in the search tool. The OEM Calibration Requirements Search is designed to provide information on the calibration requirements that are needed for vehicles equipped with advanced driver assistance systems (ADAS). This includes systems such as adaptive cruise control, lane keep assist, and collision braking.

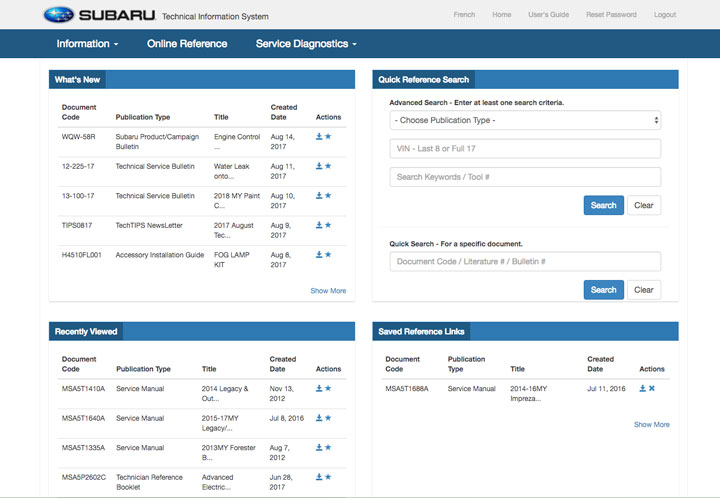

Subaru has changed the layout of their repair information website. You will notice that the site has a new look and improved navigation. Convenient new features make finding repair information easier. Let’s take a look at what has changed.

A key part of being able to diagnose a problem with advanced driver assistance systems (ADAS) is understanding how the system works. Knowing what is happening inside the system will help you properly diagnose why the system may be failing. This will prevent replacing parts that are not causing the system issue. Let’s take a look at the inner workings of a park assist system.

A key factor in collision repair is making long-lasting repairs. When a vehicle is repaired, many areas of corrosion protection are disturbed. This creates corrosion hot spots that left untreated will lead to corrosion and potentially a repair failure. However, there are certain precautions that can be taken to safely and properly restore the corrosion protection throughout the repair process. OEMs often give specifications on restoring corrosion protection. These specifications generally include seam sealer, adhesives, foam fillers, and cavity waxes. Let’s take a look at what Jaguar Land Rover (JLR) says.

The addition of the OEM Calibration Requirements Search to the RTS portal was a big step for the collision industry. While this new feature has been well received, there has been some confusion about what is included in the search tool. The OEM Calibration Requirements Search is designed to provide information on the calibration requirements that are needed for vehicles equipped with advanced driver assistance systems (ADAS). This includes systems such as adaptive cruise control, lane keep assist, and collision braking.

What is the MPa of the front lower rail? What is the outer uniside made of: steel, aluminum, or composite? Can heat be used to straighten or is it cold straightening only? What are the repair limitations? These are just some of the questions that the RTS team fields on a daily basis.

As the industry continues to ask if pre- and post-repair system scanning is necessary, Toyota/Lexus/Scion provides their answer.

Are you wondering if a particular OEM or organization has a published statement on pre-repair and post-repair scanning? We have compiled a list of most of the statements on the subject, so you can...

Since advanced driver assistance systems (ADAS), scanning, and calibration first started becoming relevant, members of the collision repair industry have required as much knowledge as possible on...

Honda /Acura has updated their position statement on pre- and post-repair scanning to give more clarification on what is expected for scanning.

BMW has released a position statement related to pre- and post-repair system scanning. The statement applies to All vehicles equipped with on board diagnostics II (OBD II).

The I-CAR best practice article, Recycled Outer Quarter Panels w/Rolled Hem Flanges has gotten a lot of interest from the collision repair industry. It’s important to know which vehicles are...

As the industry continues to ask, are pre- and post-repair scans necessary, General Motors provides their answer.

Over the past few months, we've been sharing OEM position statements on restraints wiring repairs. Now we're bringing them all together in one place for easy reference.

FCA/Stellantis has released a position statement related to pre- and post-repair system scanning.

Nissan/INFINITI updated their position statement on pre- and post-repair scanning. The revised position statement touches on more subjects and gives additional information on the subject.

Repairer Driven News (RDN) released an article featuring an updated Rivian procedure.

What is the MPa of the front lower rail? What is the outer uniside made of: steel, aluminum, or composite? Can heat be used to straighten or is it cold straightening only? What are the repair...

I-CAR had a discussion on 2020-2025 Ford Explorer rear rail sectioning.

The intermingling of technology and automobiles continues, with digital key offerings from most vehicle makers. Digital keys utilize smartphone technology to expand vehicle access and owner...

Have you had an experience where the vehicle notified the owner that it was being moved while it was in your repair facility? App-based connected services are available from many vehicle makers and...

When an accident happens, how will you call for help? Maybe the telematics system, equipped with a backup battery, could automatically do this, even if the main power is cut off. What are the repair...

While looking at repair procedures in a body repair manual (BRM) you may notice that symbols are used to indicate specific operations or parts to be used during the repair process. Most BRMs provide a...

Sometimes seeing is understanding, that’s why I-CAR's technical team created the Just in Time video series to guide you through a variety of collision repair topics from ADAS and EVs to repair tips...

Sometimes seeing is understanding, that’s why I-CAR's technical team created the Just in Time video series to guide you through a variety of collision repair topics from ADAS and EVs to repair tips...

The summer edition of General Motors (GM) Repair Insights is now available.