Close

Your job requires that you keep on top of the latest in vehicle, tool, and equipment technology – I-CAR is committed to helping you do so in one convenient place. We regularly publish new articles highlighting the latest and greatest collision repair information.

So check back often and follow us on X @Ask_ICAR to ensure you’re equipped with the most up-to-date collision repair technical information available in the industry.

Why MIG Brazing?

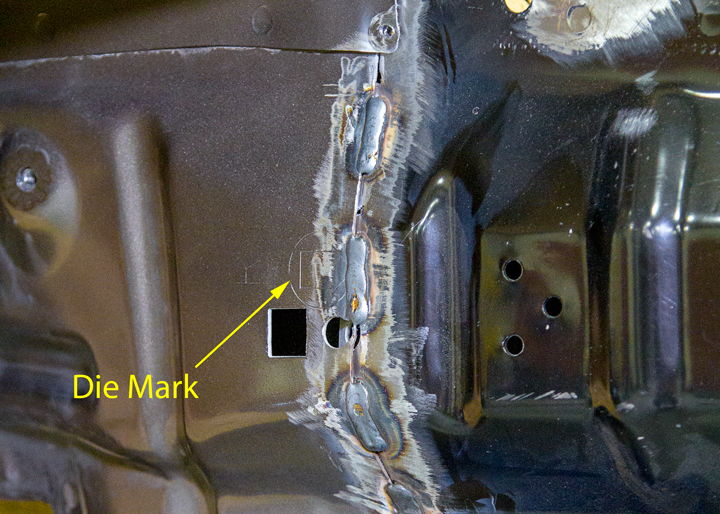

It is widely known that GMA welded; fully galvanized steel will lose some of its properties, including corrosion protection, due to the heat created during welding. OEMs are starting to counter this problem by using MIG brazing along with "stitch" and "skip" methods to control the heat. However, MIG brazing should only be done in areas specified by an OEM procedure. With MIG brazing, the lower heat input burns away a minimal amount of the zinc corrosion protection (galvanizing) adjacent to the weld (see Figure 1).

It's just a recommendation, if they wanted me to follow it, they would call it a requirement, right? Wrong!

Knowing whether or not a part is made of boron-alloyed steel is important for repairs and replacement. OEM repair information is the best source to identify if a part is UHSS.decisions. The location of the part can be used to determine if the part is likely to be an ultra-high-strength steel (UHSS) part. However, part location is not definitive, the part could be boron-alloyed steel or it could be a part that is below 600MPa steel. The location will help to prompt further research into straightening, sectioning, or replacing at factory seams. Steel identification may also help determine removal and attachment methods.

With the use of advanced materials constantly increasing, it is hard to know where to start. I-CAR has addressed the first step to this common issue with the first two columns in the OEM Technical Information Matrix: the Body Construction Materials Identification column and the Body Construction Material Repair Guidelines column. Let's take a brief look at each one.

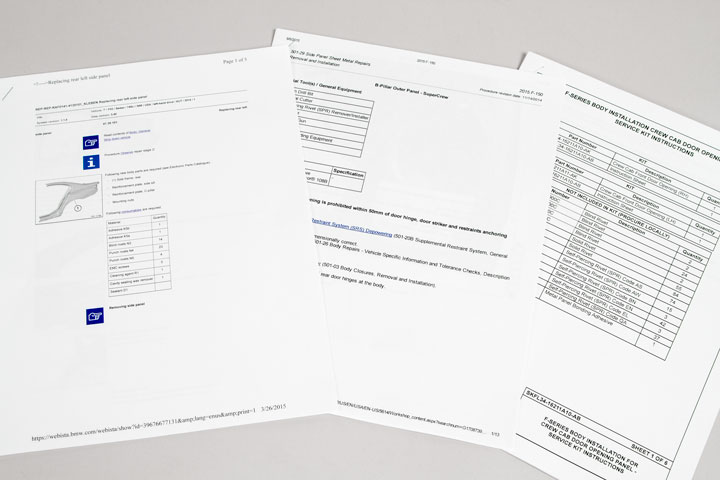

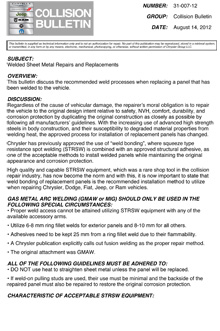

So you've got a Chrysler sitting in your repair facility and a service part, but no installation procedure. What do you do? On any other steel vehicle, you would duplicate the original attachment method and plug welds are ok, but not a Chrysler.

Repairing mild steel body panels with collision damage is nothing new. Using hammers, dollies, and picks when access to the backside is obtainable is a very common practice for straightening. With areas of limited access to the backside, using a weld-on dent puller for straightening is also quite common. So why does this change when dealing with an aluminum exterior panel?

In your recent pursuit of late-model Ford sectioning information, you've scanned past the term "lap-joint backer plate" in their body repair manuals. Wait a minute, pause, rewind, what is a lap-joint backer plate and how do you make that?

"NOTE: The following steps provide a general guideline for replacement of body structure components. Refer to exploded views for specific component and assembly information." Additionally Ford says "Where possible, create a backer piece using a portion of the old panel. This will create a stronger joint."

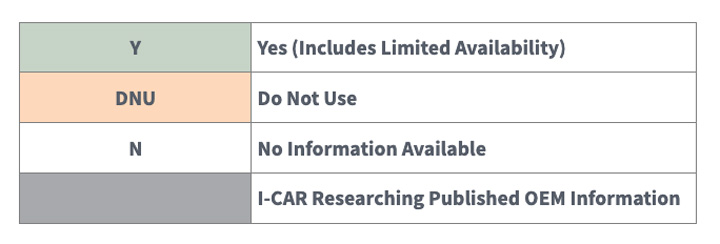

When going through a collision repair manual, it is important to know what the symbols and colors mean. The same holds true when using the I-CAR developed OEM Collision Repair Information Matrix. Let's take a closer look at the key that identifies the status of each vehicle maker on the I-CAR developed OEM Technical Information Matrix.

When it comes to repair information, vehicle makers use a wide variety of terminology for replacement parts. All of the different names can be confusing, especially when repairing a variety of vehicle makes and models.

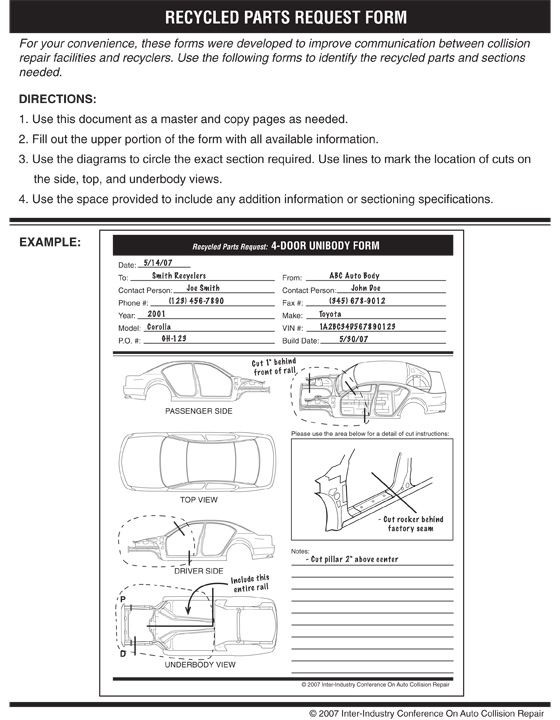

Have you misplaced your copy of the I-CAR Recycled Parts Request Form? Let us help you.

Here is a link to download your copy of the I-CAR Recycled Parts Request Form.

When it comes to repair information, vehicle makers use a wide variety of terminology for replacement parts. All of the different names can be confusing, especially when repairing a variety of vehicle makes and models.

While doing research to update the OEM Partial Part Replacement Search we found there were several model years from Subaru that did not have a collision repair manual.

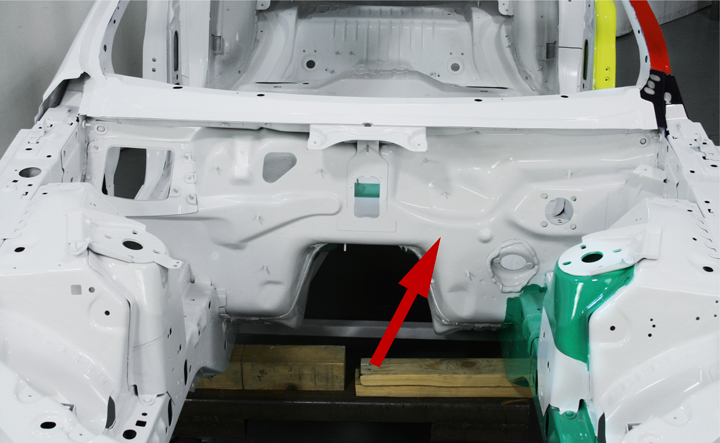

A cowl may also be referred to as a firewall or dash panel. It is common for cowls to be multi-piece parts. Typically, if the part is sold by the vehicle maker, it can be replaced as supplied. A cowl may have one or multiple layers of sheet metal. When this type of part is replaced, make sure to maintain the same panel layering as the original part.

As the industry continues to ask if pre- and post-repair system scanning is necessary, Toyota/Lexus/Scion provides their answer.

Are you wondering if a particular OEM or organization has a published statement on pre-repair and post-repair scanning? We have compiled a list of most of the statements on the subject, so you can...

Since advanced driver assistance systems (ADAS), scanning, and calibration first started becoming relevant, members of the collision repair industry have required as much knowledge as possible on...

Honda /Acura has updated their position statement on pre- and post-repair scanning to give more clarification on what is expected for scanning.

BMW has released a position statement related to pre- and post-repair system scanning. The statement applies to All vehicles equipped with on board diagnostics II (OBD II).

The I-CAR best practice article, Recycled Outer Quarter Panels w/Rolled Hem Flanges has gotten a lot of interest from the collision repair industry. It’s important to know which vehicles are...

As the industry continues to ask, are pre- and post-repair scans necessary, General Motors provides their answer.

Over the past few months, we've been sharing OEM position statements on restraints wiring repairs. Now we're bringing them all together in one place for easy reference.

FCA/Stellantis has released a position statement related to pre- and post-repair system scanning.

Nissan/INFINITI updated their position statement on pre- and post-repair scanning. The revised position statement touches on more subjects and gives additional information on the subject.

Repairer Driven News (RDN) released an article featuring an updated Rivian procedure.

What is the MPa of the front lower rail? What is the outer uniside made of: steel, aluminum, or composite? Can heat be used to straighten or is it cold straightening only? What are the repair...

I-CAR had a discussion on 2020-2025 Ford Explorer rear rail sectioning.

The intermingling of technology and automobiles continues, with digital key offerings from most vehicle makers. Digital keys utilize smartphone technology to expand vehicle access and owner...

Have you had an experience where the vehicle notified the owner that it was being moved while it was in your repair facility? App-based connected services are available from many vehicle makers and...

When an accident happens, how will you call for help? Maybe the telematics system, equipped with a backup battery, could automatically do this, even if the main power is cut off. What are the repair...

While looking at repair procedures in a body repair manual (BRM) you may notice that symbols are used to indicate specific operations or parts to be used during the repair process. Most BRMs provide a...

Sometimes seeing is understanding, that’s why I-CAR's technical team created the Just in Time video series to guide you through a variety of collision repair topics from ADAS and EVs to repair tips...

Sometimes seeing is understanding, that’s why I-CAR's technical team created the Just in Time video series to guide you through a variety of collision repair topics from ADAS and EVs to repair tips...

The summer edition of General Motors (GM) Repair Insights is now available.